When I changed the rims on my Acura RSX Type S, I decided to use DC5 Type R rims. I made the mistake of initially using aftermarket lug nuts with a conical seat, which was incorrect for the rims. Had I not caught the mistake, I would have damaged the rims. The right lug nut type for Honda cars, including my Acura, is a ball seat lug. Using the correct lug nut type is essential for both safety and performance. This experience underscored the importance of matching the right lug nut types to ensure the integrity of my wheels and vehicle performance.

The moral of this story is always make sure to use the right lug nuts for your specific wheels and vehicle to avoid potential damage and ensure a safe, smooth ride.

What Are Lug Nuts & How Do They Work?

There are a lot of important parts on your vehicle, from brakes and struts to your tires and steering components. But the lug nuts that hold your wheels in place are some of the most vital. These small parts ensure the wheel and tire assembly stay firmly attached to your vehicle. Whether you’re upgrading the look of your wheels with new lug nuts, buying custom wheels, or simply replacing worn or cracked ones, getting the right type of lug nut is crucial for safety and performance.

Different Types of Lug Nuts

There are many different types of lug nuts used by auto and wheel makers today. The important aspects of any lug nut are the thread and the point where it meets the wheel, also called the lug seat. Below are the most popular lug nuts on the market today and their wheel compatibility based on the lug seat.

Spherical/Ball Seat Lug Nut: Spherical or ball seat lugs have a rounded seat. Honda/Acura uses this as their OEM choice.

Conical/Tapered Seat Lug Nut: These are among the most utilized types of lug nuts. Conical or tapered lugs feature a cone-shaped seat.

Flat Seat Lug Nut & Mag Seat Lug Nut: These lug nuts feature a seat that looks like a washer. Mag seat lugs have a longer threaded area.

Variations of Lug Nut Types are designed based on the 3 core types above:

Extended Thread Seat Lug: With a longer threaded area for longer bolts, these lugs require a special socket key for removal.

Tuner Style Lug Nut: Often used to prevent theft, these lugs feature a conical seat and require a special socket key to remove them.

Small Diameter Drive Seat Lug Nut: Used to prevent theft, these conical seat lugs require a special socket key for removal.

Two-Piece Lug Nut: Some truck manufacturers use two-piece lug nuts. While engineers have shown these to be viable and strong lug nuts, over time water can get between the cap and base, causing swelling. This can make it difficult, and sometimes impossible, to remove the lug with normal tools.

Different Sizes of Lug Nuts

Like any car part, it’s important to know the size you need for your vehicle. Check your owner’s manual and look for the stud diameter and thread pitch. Then look for lugs that fit the seat of your wheels as well as the diameter (the first number in the set) and thread pitch (the second number). The diameter of the stud is the first number. The second is the thread pitch in either metric (distance between each thread) or standard (number of threads per inch).

Thread Diameter and Pitch

The most common sizes include: 10mm x 1.25, 12mm x 1.25, 12mm x 1.50, 12mm x 1.75, 14mm x 1.25, 14mm x 1.5, 14mm x 2.0, as well as 7/16″ x 20, 1/2″ x 20, and 9/16″ x 18.

What Is Lug Nut Torque?

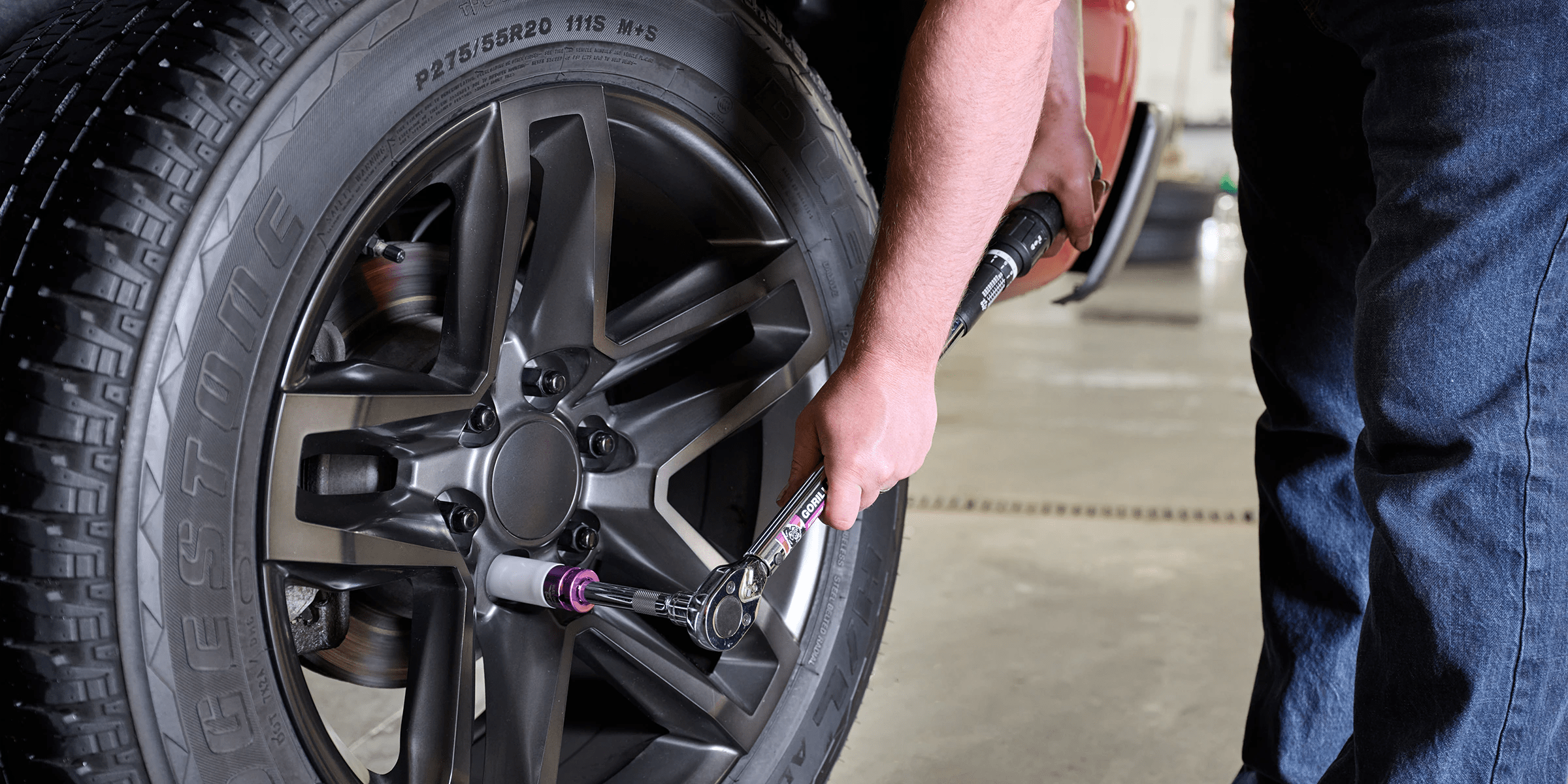

Lug torque is the amount of recommended force (measured in foot-pounds) that should be applied to a lug nut to ensure it stays firmly attached. Generally it’s roughly 78-80 ft lbs, but refer to the owners manual of your car make and model for exact specs. Lugs that are under-tightened can wiggle loose or vibrate around the hub causing damage or even worse, fall off. Tightening a lug too much can cause damage to the bolts on the wheel hub assembly. Again, the correct torque can be found in your vehicle owner’s manual. A few blog posts ago however, I wrote about torque wrenches types and this is still the best way to tighten your lug nuts to spec to ensure you get the maximum amount of performance and safety.

In addition to this, the torque tightening pattern for wheels is a crucial procedure to ensure even distribution of pressure across the wheel mounting surface, preventing warping and ensuring the wheel is securely attached. Typically, this involves tightening the lug nuts in a star or crisscross pattern. Starting with one lug nut, you then move to the lug nut opposite to it, continuing in this alternating fashion until all lug nuts are properly torqued to the manufacturer’s specifications. This method ensures that the wheel seats evenly on the hub, reducing the risk of vibration, misalignment, or wheel detachment.

If the lug nuts on your vehicle are damaged and need to be replaced, or you’re simply going for a new look, replacing yours doesn’t require lifting your vehicle. All you need is a torque wrench, the right size socket, and a few minutes.

- Using the right size lug wrench, remove one of the lug nuts from one of the wheels.

- Carefully thread the new lug nut in place and tighten (torque) the lug to the manufacturer’s specifications based on the hub, thread pitch, and stud diameter.

- Repeat the process in a crisscross pattern, removing and replacing only one lug at a time.

When Should I Replace My Lug Nuts?

The original equipment (OE) lugs that came with your vehicle should last for many years. But over time, they can develop rust, cracks, and more. They can even swell, making it difficult to remove them with a standard lug wrench. It’s time to replace your lug nuts if the threads are stripped or showing signs of slipping, cracked, damaged from deicer, the seat is worn and unable to stay in place, or when you get a new set of custom wheels.

Can I Use Aftermarket Lug Nuts?

Aftermarket lug nuts, as well as custom wheels, can give your car or truck a new look. When shopping for aftermarket lug nuts, be sure they are original equipment (OE) compatible with bolts on your vehicle’s wheel hub assembly. Chances are, if you are getting new aftermarket wheels, it’s best to pair a new set of after market lug nuts that match it based on the type, either conical, ballseat, or something else. In most cases, conical lug nut type is what I see most aftermarket wheels have including Spoon, Rays, Muteki, etc.

Aftermarket lug nuts, as well as custom wheels, can give your car or truck a new look. When shopping for aftermarket lug nuts, be sure they are original equipment (OE) compatible with bolts on your vehicle’s wheel hub assembly. Chances are, if you are getting new aftermarket wheels, it’s best to pair a new set of after market lug nuts that match it based on the type, either conical, ballseat, or something else. In most cases, conical lug nut type is what I see most aftermarket wheels have including Spoon, Rays, Muteki, etc.

If you are running OEM wheels, it’s best to use the right lug nut type for the wheel, which for a Honda OEM wheel is a ball seat lug nut type.